Certifications: ISO9001:2008 I TS16949

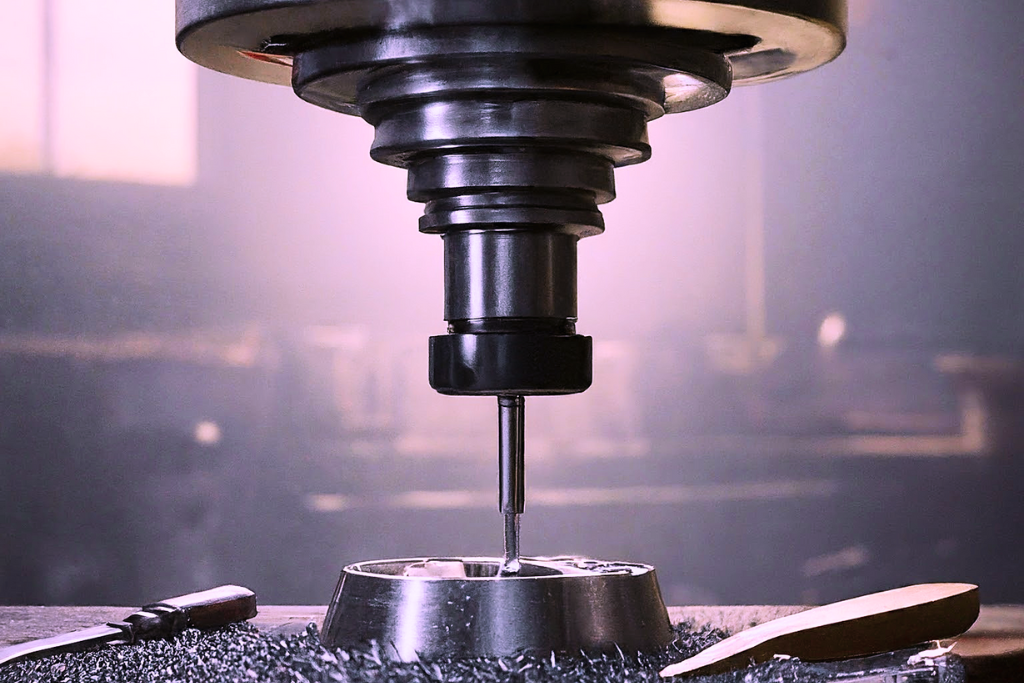

CNC Milling Service

Instant quotes, FREE rush production and FREE shipping on samples.

- No minimum quantities

- Parts starting at < $1 ($29 minimum order)

- 2-4 day production on standard orders

- Tight Tolerances as your request

- Free design feedback & instant quotes

- Free shipping on samples, and only $18.50 for 0.5kg to USA!

Our CNC machines produce parts with tight tolerances and surface finishes up to 32 μin. (0.8 μm). Our in-house services, including prototyping, tooling, and assembly, allow us to complete every manufacturing process step. As a result, we can produce complex parts—from prototypes to end-use production—in as little as one day.

Our equipment includes 3-axis milling, 5-axis indexed milling, and 5-axis simultaneous milling. Our milling experts combine more than 30 years of industry experience with CAD/CAM software, precision machining, and CNC milling to produce high-quality, complex plastic and metal parts.

Our CNC milling service is commonly used for:

- Complex shapes and profiles.

- Deep, long or narrow cavities.

- Multi-tool machining.

- Prototypes, one-offs, and replacement parts.

3-Axis CNC Milling

It is a process that involves the movement of 3 axes simultaneously unless the desired product is produced. Typically, the material moves back and forth, up and down, and side to side. Technically, it is a basic machining process beneficial for manufacturing relatively simpler and uncomplicated shapes.

4-Axis CNC Milling

This type of CNC milling uses four-dimensional axes to create a piece of desired size and profile, machining a product by moving the four axes. Namely, the X, Y, Z, and A axes rotate simultaneously to fulfill operations. Generally, the process is helpful when the cutting has to be carried out at the sides of an object.

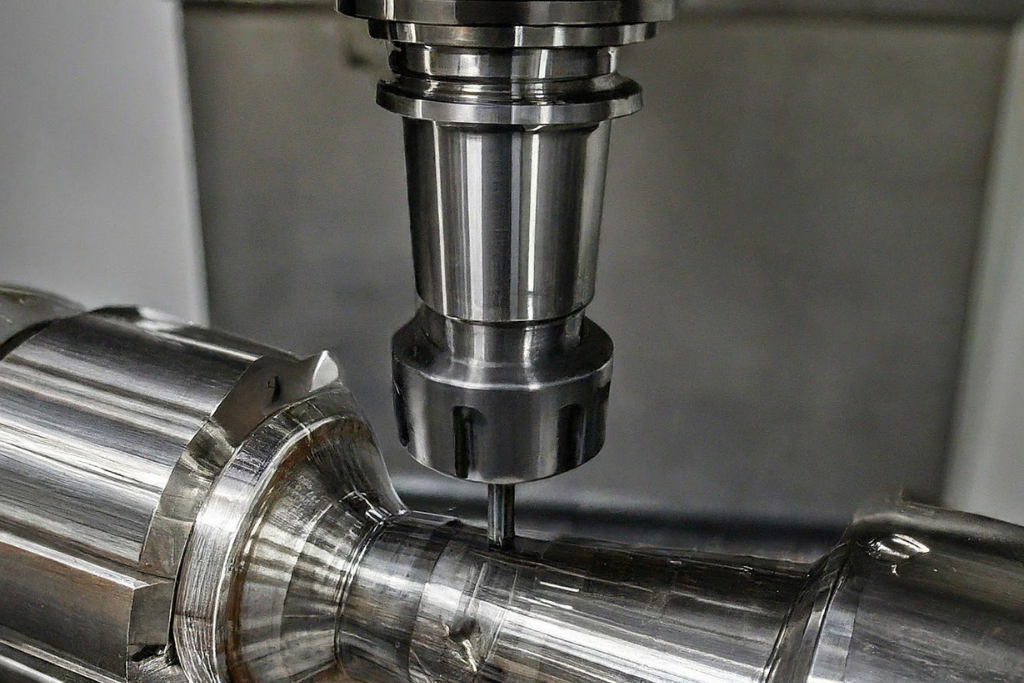

5-Axis CNC Milling

The 5-axis milling process has X, Y, Z, A, and B axes to operate. It is popular due to its single-step machining dynamics. Moreover, it is the most advanced milling process helpful in manufacturing intricate parts such as artificial bones, titanium pieces, the aerospace industry, and other architectural products.

5-Axis CNC Milling

5 Axis machining allows the creation of incredibly complex shapes. With skilled workers and a five-axis CNC machine, we can keep producing these complex shapes, consistently turning out exceptional parts that demonstrate the highest quality standards. We can meet your needs if you need a tricky prototype realized or have finalized your prototype and require a well-established, capable machining company to take over production.

No matter how many parts your assembly is composed of, we can handle all aluminum milling projects requiring high precision and complex shape machined parts and provide highly tight tolerances and excellent surface finishes to meet your most complex manufacturing challenges.

Advantages of 5-Axis Milling Aluminum

- The machine is on five sides of a part with one single setup. Saves set up time, increasing machining productivity.

- Higher accuracy and outstanding surface finish, improving overall part quality.

- Workpieces are not moved through several workstations, which reduces error and fixturing costs and less time hand benching in a CNC router.

- Milling and drilling with compound angles. Improved tool life and cycle time resulted from tilting the tool/table to maintain optimum cutting position and constant chip load.

- Shorter and more rigid tools may be used. Higher spindle speeds and feed rates may be achieved on the CNC router while reducing the load on the cutting tool.

CNC Milling Services Worth Buying

For decades, GY has been serving its clients at wallet-friendly rates. We have invested in machines and trained staff to generate products at pocket-friendly prices.

Whether you require a prototype or CNC machining complicated parts, there is no manufacturer better than us.

Our ultimate goal is to build long-term relationships with our customers, and the ultimate way of doing so is by offering top-quality products at reasonable prices.

Advantages Of GY CNC Milling Services For Product Developers

CNC milling services at GY have many advantages for product development that can make it the ideal solution for rapid prototyping and volume production. Here is what you should consider.

CNC Milling Materials

GY Milling Services simplifies the process of manufacturing custom machined parts. We make it easy for your company to design and implement precision machining solutions.

Brass is a metal alloy with good machinability and excellent electrical conductivity. Ideal for applications that require low friction.

Brass HPb63 / HPb62 / HPb61 / HPb59 / H59 / H68 / H80 / H90, etc.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. When it comes to tensile strength, stainless steel is superior to materials like aluminum, brass, and mild steel.

—————————————————————

Stainless Steels Available

Stainless steel 201

Stainless steel 301

Stainless steel 303

Stainless steel 304

Stainless steel 316

Stainless steel 416

Stainless steel 430

Stainless steel 440C | 1.4125 | X105CrMo1

Titanium has the lowest density of all metallic elements. Titanium alloys are 50% heavier than steel but 7-10 times stronger. Can be anodized in many colors.

Corrosion resistant, even in sea water, aqua regia and chlorine. Also, it is non-toxic, non-allergenic and perfectly compatible with the human body.

—————————————————————

Titanium Materials Most Used

TA1 / TA2 / TC4 (Ti 6Al-4V)

Nylon is a strong, stiff engineering plastic with outstanding bearing and wear properties. The PA66 nylon material is strong, with high-temperature strength, versatile, durable, especially when reinforced, electrically conductive and shielding, making it useful for electrical and automotive.

ABS is a low cost engineering plastic that is easy to machine and fabricate. An ideal material structural applications when impact resistance, strength, and stiffness are required. ABS plastic is also considered food safe.

Acrylic is a rigid and transparent thermoplastic material. It is also referred to as Polymethyl methacrylate (PMMA). It is a colorless and clear polymer that can come in different forms. For example, it comes as small granules, pellets, or sheets.

Polycarbonates, more commonly known as PC, is a naturally transparent thermoplastic. The raw material allows for the internal transmission of light with nearly the same capacity as glass but with a lighter weight, especially useful when the product requires outstanding resistance to impact and / or good transparency.

PVC has excellent corrosion, flame and water resistance, with high strength, impact resistance and overall toughness. PVC is ideal for applications in building, construction, electronics and transportation sectors.

PTFE as an advanced engineering material has a variety of benefits. It is used for handling and storing corrosive chemicals as well as coating parts such as bearings and screws.

Being hydrophobic, non-wetting, high density and resistant to high temperatures, PTFE is an incredibly versatile material with a wide variety of applications, though it’s perhaps best-known for its non-stick properties. Also it is FDA approved and food-safe.

Polyethylene terephthalate, more commonly known as PET, is a lightweight clear plastic that’s used for countless packaging applications. PET is highly flexible, colorless, and semi-crystalline. Depending on how it’s processed, PET can be rigid to semi-rigid.

Polyetherimide (PEI) is an amorphous thermoplastic resin with amber transparency, The resin is characterized by high deflection temperature (200°C at 264 psi), high tensile strength and flexural modulus (480,000 psi), and very good retention of mechanical properties at elevated temperatures. It has unique combination of high specific strength, rigidity, flexibility, exceptional dimensional strength etc.

High-performance thermoplastic material, unreinforced PolyEtherEtherKetone (PEEK), semi-crystalline, granules for

injection molding and extrusion, standard flow, FDA food contact compliant, color natural/beige.

Polypropylene (PP) is a commercially important polymer used in a variety of applications owing to its low cost. It is a commodity plastic with low density and high heat resistance. Suitable for making general mechanical parts, corrosion-resistant parts and insulating parts.

Carbon Fiber is a polymer and is sometimes known as graphite fiber. It is a very strong material that is also very lightweight. Carbon fiber is five times stronger than steel and twice as stiff. Though carbon fiber is stronger and stiffer than steel, it is lighter than steel, making it the ideal manufacturing material for many parts. These are just a few reasons why carbon fiber is favored by engineers and designers for manufacturing. Colors: Shinny, Matte, Blue, Red, Grey.

Why Choose US?

Working with market leaders in the On-demand manufacturing industry, without the busyness and risk.

No MOQ

One-off aluminum prototype part or large quantity parts. No matter the size of your order, we can handle it.

Low Cost

After 12 years of experimenting with new technologies, GY has come up with high-quality products at cheap rates. You can trust us for reasonable prices.

Fast delivery

We have 40 machines with a whole production process, take your project from design to delivery faster than our competitors.

Quality is Our Top Priority

We use advanced production technologies and strict control systems to ensure high quality. More importantly, the quality-oriented attitude has been so entrenched in the mind of every single employee.

How to Get Your CNC Milling Parts?

4 Simple Steps

Upload a CAD File

Quote & Design Analysis

You’ll receive a quote in 4-8 hours, and we will propose the most economical and suitable solutions for you until you say “yes”.

Order Confirmation

Once you confirm the first samples and place an order, we’ll start milling mass parts and surface finish work. Communicate in time if there are any problems in production.

Parts are Ready

100% quality inspecting on each part before shipping, you will receive products in 7-10 days by air. We are responsible for any issues in transit, including damages or lost parcels.

Get A Quick Quote

We always insist on high quality and cost-effective products, contact us today to get an accurate quotation.