Custom Machined Copper Parts Made Easy

Get machined metal copper prototypes and production parts at consistently low prices.

- Free Design and Provide Solutions.

- No Minimum Order Quantities, ≥1.

- 100% Quality Guaranteed.

- All uploads are secure and confidential.

- All uploads are secure and confidential.

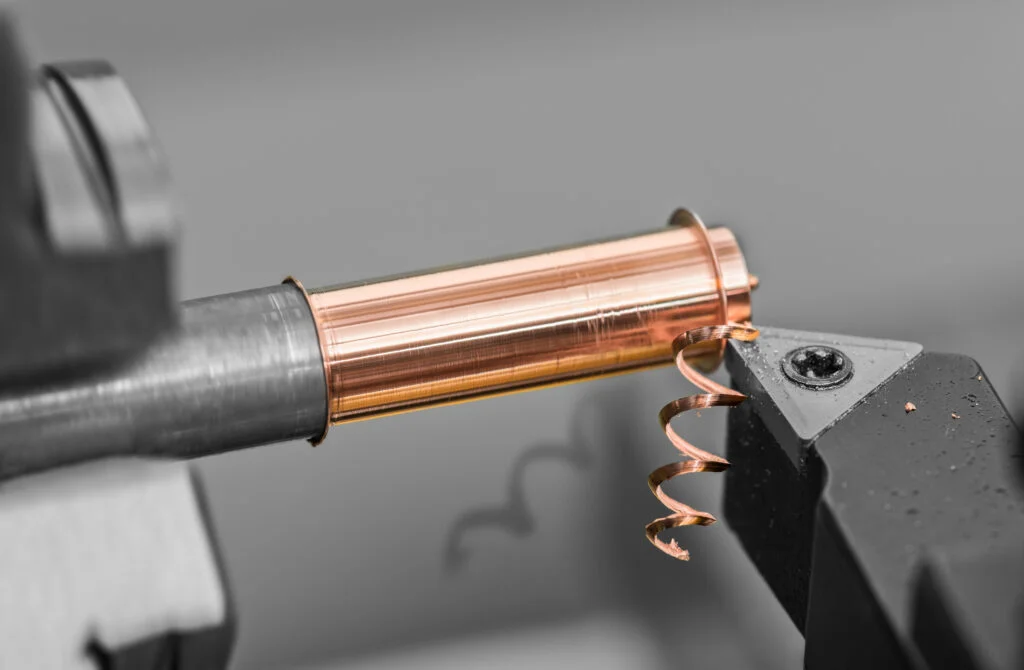

Completed operations include milling, slotting, drilling, tapping, counterboring, chamfering, threading, knurling, brazing, grooving, trimming, and nickel plating.

Why GY Excels in Copper Machining?

1. Specialized Copper Expertise

17+ Years of Focus: We’ve perfected techniques to overcome copper’s stickiness and thermal expansion

Alloy-Specific Solutions: From soft C11000 to tough C17200 beryllium copper

2. Proprietary Anti-Galling Process

- Diamond-coated tooling with optimized RPM/feed rates

- Custom coolant formulas to prevent material buildup

- Mirror finishes achievable without post-polishing

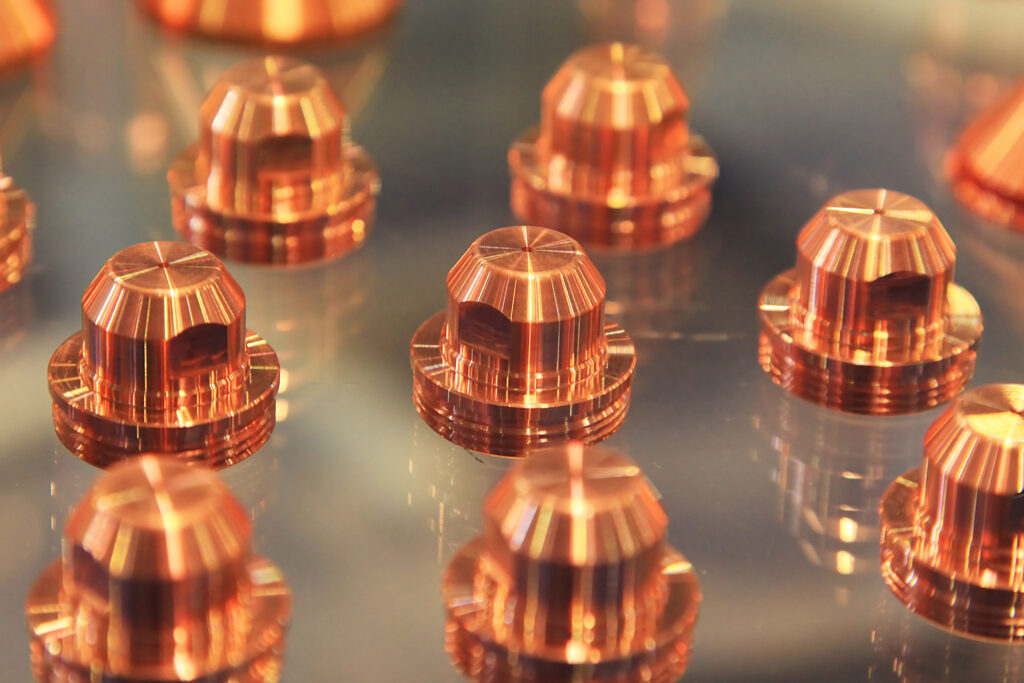

3. Precision That Powers Industries

- ±0.005mm tolerances for RF waveguides and laser components

- True-position accuracy within 5 microns for electrical contacts

- Micro-machining capability down to 0.1mm features

See the GY Difference

• 30% longer tool life vs. industry average

• 99.97% on-time delivery for copper components

• Zero conductivity-reject parts since 2022

Copper Properties

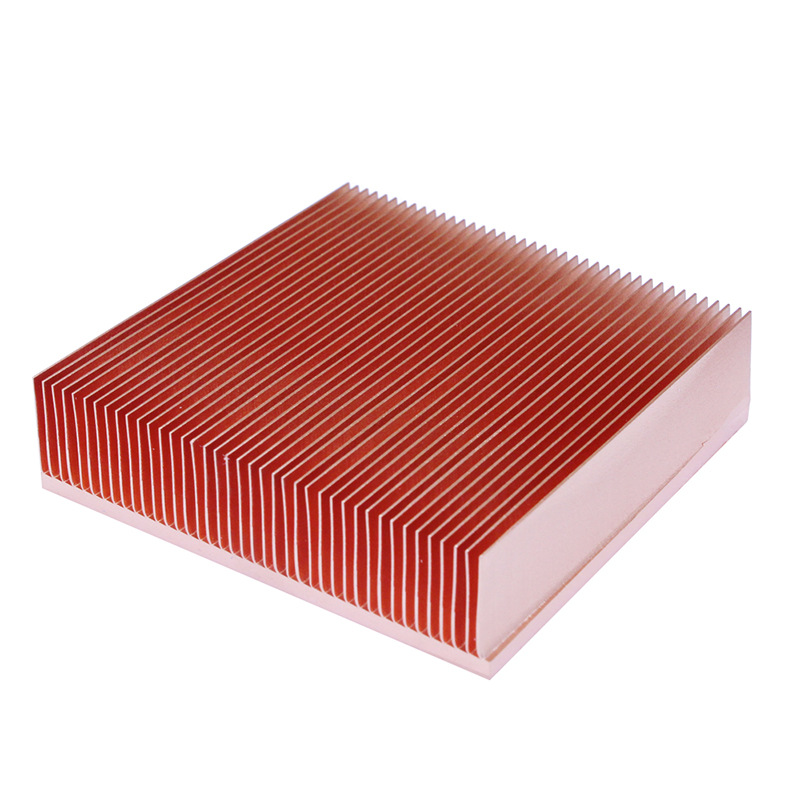

✅ Exceptional Conductivity

Best electrical & thermal conductivity among industrial metals (only silver outperforms)

Ideal for heat exchangers, electrical components, and energy applications

✅ Natural Antimicrobial

Kills 99.9% of bacteria* on surfaces within 2 hours (*EPA-registered)

Critical for healthcare, food processing, and high-touch surfaces

✅ Superior Machinability

Softer than steel but requires specialized tooling to prevent galling

Excellent for precision-turned parts and complex geometries

✅ Corrosion Resistant

Forms protective patina that slows further oxidation

Maintains performance in harsh environments

✅ 100% Recyclable

Retains properties indefinitely through recycling

Sustainable choice for eco-conscious manufacturers

We carry two grades of copper for CNC machining:

C36000 (Free-Cutting Brass)

Superior Machinability: Highest machinability rating among copper alloys; minimal tool wear, ideal for high-speed operations.

Smooth Finish: Produces clean, burr-free edges, reducing post-processing.

C10100 (Oxygen-Free Copper)

High Conductivity: Perfect for electrical/thermal components; retains purity after machining.

Ductility: Easily formed into complex shapes without cracking.

Application:

- Bearings

- Bushings

- Valves

- Gears

- Compression Fittings

- Medical Transmissions Components

- Pipe Fittings

- Nuts, bolts, threaded parts

- Electrical terminals

- Electrical wiring

- Electrical relays and switches

- Printed circuit boards

- Computer heat sinks

- Jewelry

- And more…

Gallery

We can do more than just these things…

Frequently Asked Questions (FAQ)

Can copper be CNC machined?

CNC is easy to fabricate copper. This enables us to achieve intricate shapes and design with less effort, time as well as higher precision. Copper: This pipe is made from copper and as it has soft properties, such parts are heat-treated to get the desired strength in order for them to last a long time. As the years passed, CNC machined copper parts has been in demand.

What is the best copper for CNC machine?

It is a purer material known as 101 copper that provides much better conductivity. 110 copper is usually relatively easy to machine, resulting in lower cost. Copper beryllium (CuBe) exhibits favorable strength, oxidation resistance, and non-magnetic and non-sparking properties.

Why is machining copper difficult?

Because pure copper has few impurities and good ductility, plasticity and toughness are very strong, so its difficult to machining machinery factory of metal parts. This helps because while copper can be machined with ease, alloying it makes for what are sometimes considered to be the easiest-to-machine metallic materials.

What tools are used in machining copper?

In general, high-speed steels (HSS) and cemented carbides are preferred cutting tools for copper machining. High strength and toughness, abrasion resistance and long tool life due to excellent wear characteristics.

Is copper or steel better?

Steel is a much stronger material in comparison to copper, this results in so many benefits of which one of them being that steel pipes can support their own weight for larger distances. You many need to use twice as many support brackets for even a run of copper pipe over steel.

What tool is used for cutting copper?

They are used for cutting copper, brass, steel and iron wire as well. There are those that come with insulated handles to make sure that the wires you will be working on do not shock your system. Diagonal cutters use a cross-jaw design so they trim wire at an angle and end up with flat tips.

What are the methods of manufacturing copper?

In physical chemistry, this method is known as froth flotation (wikipedia), and these steps are divided in 4 basic process: [1] froth-flotation; [2] thickening; [3] smelting; and, finally make the electrolysis.

What is the copper cutting method?

Manual methods range from saws, chisels and rotary shears to special cutting scissors. These are tools that will cut copper into the proper size or shape of your preference. It is a somewhat time consuming process, but the advantages are very notable.

Why choose copper alloys?

Pure copper is a difficult material to machine because of its high plasticity and toughness.

There are also copper alloys, such as brass, that can be milled much easier than a cast iron part because the machinability of these materials is higher.

Fast machining = lower production costs.

Natural antimicrobial properties (ideal for medical/food applications).

Combines conductivity, strength, and corrosion resistance.

What is CNC cutting speed?

Cutting speed ( V c ) is the apparent velocity with which material is removed from the workpiece surface in m/min or feet per minute. Each material has a maximum cutting speed and the set of machining conditions are different for each one.

Get A Quick Quote

We always insist on high quality and cost-effective products, contact us today to get an accurate quotation.