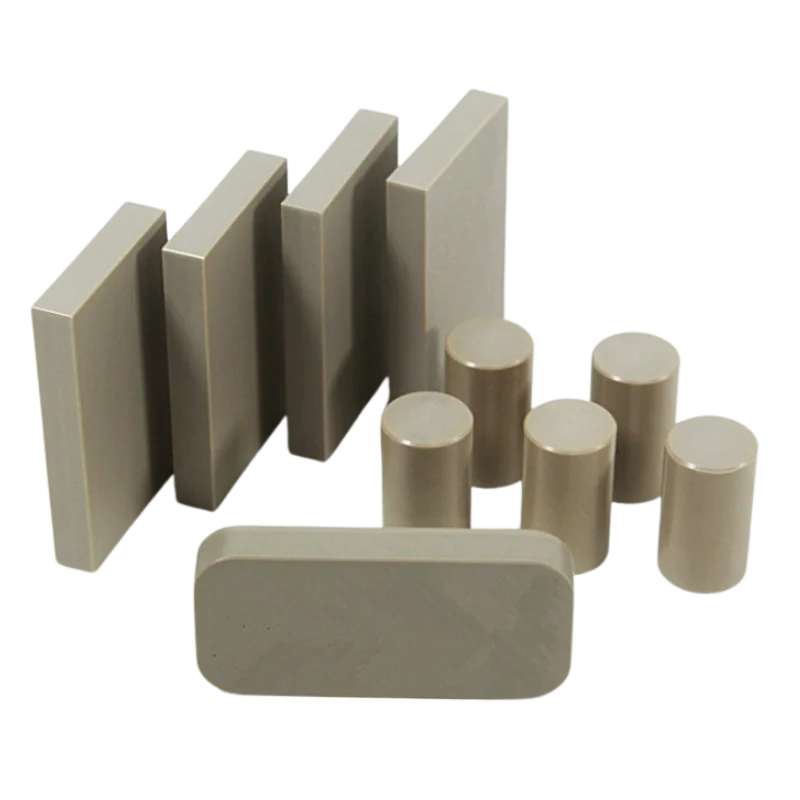

Custom Machined PEEK Parts Made Easy

Get machined plastic PEEK prototypes and production parts at consistently low prices.

- FREE design and solution

- No Minimum Order Quantity

- 100% Quality Guaranteed

- All uploads are secure and confidential.

- All uploads are secure and confidential.

PEEK or PolyEtherEtherKetone is one of the most fabulous plastics used widely in today’s world. It is a high performance material that can tough it out, Here’s what makes it so special:

Super Strong and Flexible: While being as stiff as carbon fiber reinforced PEEK it has twice a modulus of elasticity, yet this material can be bent relatively easy. This makes it ideal for making parts that must be hard, but not brittle.

Chemical Superhero: It is intended to note that PEEK cannot be defeated by hard chemicals. It can perform well in harsh conditions, which means it can be used in applications where is likely to rub against other robust materials.

Easy to Work With: This PEEK comes in the form of granules that are perfectly suitable for injection molding and for extrusion as well.

Features:

- Strong and stiff, Low friction

- Long life

- Good dimensional stability

- Exceptional insulation properties

- Excellent sterilization resistance at high temperature

- Good mechanical properties at elevated temperatures

- Hydrolysis resistance to steam, water, and sea water.

- Biocompatible

- Inherent purity

- Chemical resistant, hydrolysis resistant, autoclavable

- Very low smoke and toxic gas emissions when exposed to flame

Application:

- Bearing

- Screw

- Gear

- Pumps

- Piston parts

- HPLC columns compressor plate valves

- And more…

Frequently Asked Questions (FAQ)

Why is PEEK so expensive?

PEEK comes from petroleum-related sources – the price of its raw materials goes up and down with oil prices. While the material costs for PEEK are higher due to its rank as a specialty or engineering grade, these specific raw materials demand stands in stark contrast with other commodity plastics.

Why is PEEK strong?

PEEK is short for polyetheretherketone’, this puts it in the family of ketone polymers. This thermoplastic’s unique chemical structure allows it to have exceptional strength and stability under load, even in the most corrosive conditions.

What is the difference between PTFE and PEEK?

In PTFE, a cold shaping process itself is carried out such that the heat treatment (sintering) enables polymer particles to join together in a complex form and be processed further for any moulding. PEEK is a semicrystalline thermoplastic known for its excellent mechanical and chemical resistance at elevated temperatures.

Can PEEK be 3D printed?

PEEK can be 3D printed at temperatures ranging between 370° and450

What is the disadvantage of PEEK?

PEEK is an expensive material and it overshoots the budget for many, hence only suitable under extreme conditions. The second meaning is that this material can be very critical in the processing because you have to run it at a higher temperature than other materials, and so we typically need specialized machinery.

Is PEEK stronger than steel?

PEEK has a higher tensile strength compared to metals like aluminum and steel, as well as resistance against high heat, chemical wear over time or moisture. PEEK is even lighter than steel and aluminum but maintains astonishingly high strength due to its material properties.

Is PEEK flexible?

PEEK is a rigid material, it can still display variants of flexibility seen in other plastics (though this will largely depend on the particular grade of PEEK chosen). With a flexural modulus closest to that of human cortical bone and biocompatible properties, PEEK is well-suited for medical implants and devices.

What is the maximum temperature for PEEK?

PEEK PEEK use unlimited at 480°F (250°C) and hot water or steam with no loss of physicals PEEK is one of clearest (low haze levels) engineering films in harsh environment or high strength fluoropolymer alternatives V-0 flammability rating with very low smoke and toxic gas emission in fire. 3 ohm/cm (ISO 2577).

What is special about PEEK?

PEEK has a unique combination of mechanical properties, making it highly resistant to chemicals, wear and fatigue as well as having extremely high temperature-resistance. It has also been resistant to combustion and a good dielectric performer.

Get A Quick Quote

We always insist on high quality and cost-effective products, contact us today to get an accurate quotation.