CNC Turning Services

We use special machines to create your custom turned parts. We can make these parts really fast, sometimes in as little as one day.

- All uploads are secure and confidential.

- All uploads are secure and confidential.

GY Turning Services makes it easy to get high quality custom machined parts. With us, it is not hard for your company to devise and apply precision machining strategies.

CNC turning excels in producing:

- Functional prototypes and end-use parts

- Parts with cylindrical geometries

- Parts requiring axial and radial holes, flats, grooves, and slots.

What is CNC turning?

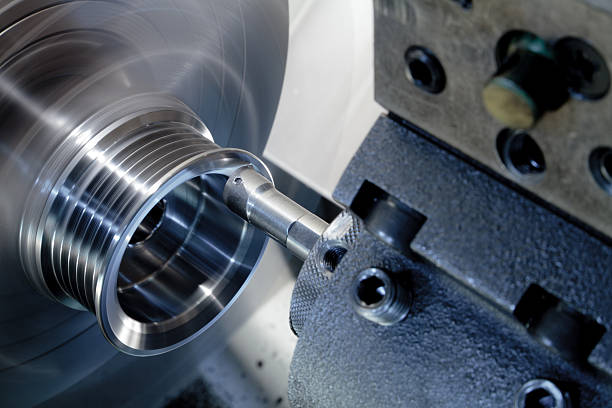

Gallery for What We Did Before

We picked out some of projects we’ve done before, not only these, but more!

Why Choose Us?

Working with market leaders in the On-demand manufacturing industry, without the busyness and risk.

No MOQ

Single or small batch of aluminum prototype part or mass production aluminum part. We can execute it with efficiency and assurance of meeting your set standards.

Low Cost

Having been in the market for 17 years experimenting with new technologies, GY has developed quality products that are very affordable. We have reasonable prices you can count on.

Fast delivery

We have 40 machines with a whole production process, We can take your project from design to delivery faster than the competition.

Get A Quote Now!

Get Your Customized Turning Parts in Just 4 Simple Steps

Step 1: Digital Consulting

Submit your CAD files through online quoting platform.

Step 2: Confirm Specs

Design your custom parts and select your preferred lead time.

Step 3: Manufacturing

Fast turnaround! Orders go straight to production for instant delivery.

Step 4: Quality Control

We manufacture your parts followin global standards and ensure highest quality.

Step 5: Delivery

we carefully pack and ship all your parts to arrive safely

Frequently Asked Questions (FAQ)

Q: What are CNC turning centers?

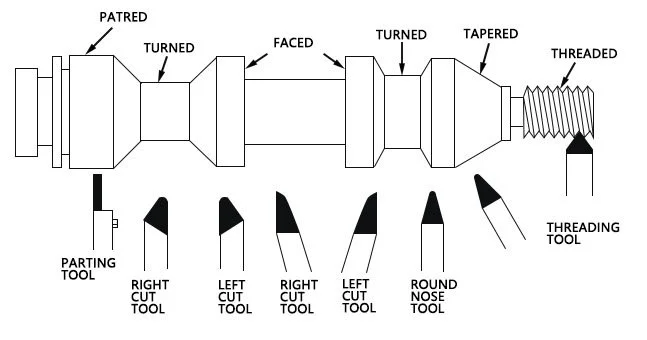

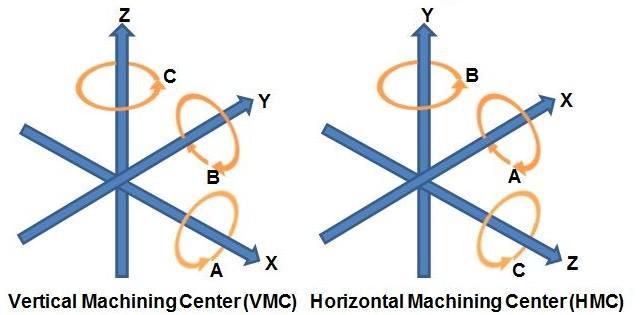

A: CNC turning centers are modern computer numerical controlled machines. Machines used in turning can have 3, 4, or even 5 axes and cutting tools such as milling, drilling, tapping, and the obvious turning.

What is the difference between a turning center and a mill turn center?

What is CNC turning used for?

What is a CNC turning job?

Computer numerical control

What is the objective of CNC turning?

Accuracy and Fineness: With CNC turning, the parts are turned with great precision which is essential for complex shapes. Efficiency: Owing to the high speed that is associated with the production process, CNC turning is considered to be a fast process. Versatility: They can make almost any shape and size that one may desire from a given material.

Ability to produce many shapes and forms

What are the basic axes of a CNC turning center?

A: They are equipped with X axis, Z axis, and one rotary axis, the so-called “C” axis.

What is the CNC turning process?

What are the disadvantages of CNC turning?

- Cost: CNC machines are generally costly and capital intensive than the other conventional machines that are used with the help of hands. . ..

Skills Loss: This means that as the employment for manual machine operators hence reduces, fresh learners do not learn those skills.

Get A Quick Quote

We always insist on high quality and cost-effective products, contact us today to get an accurate quotation.