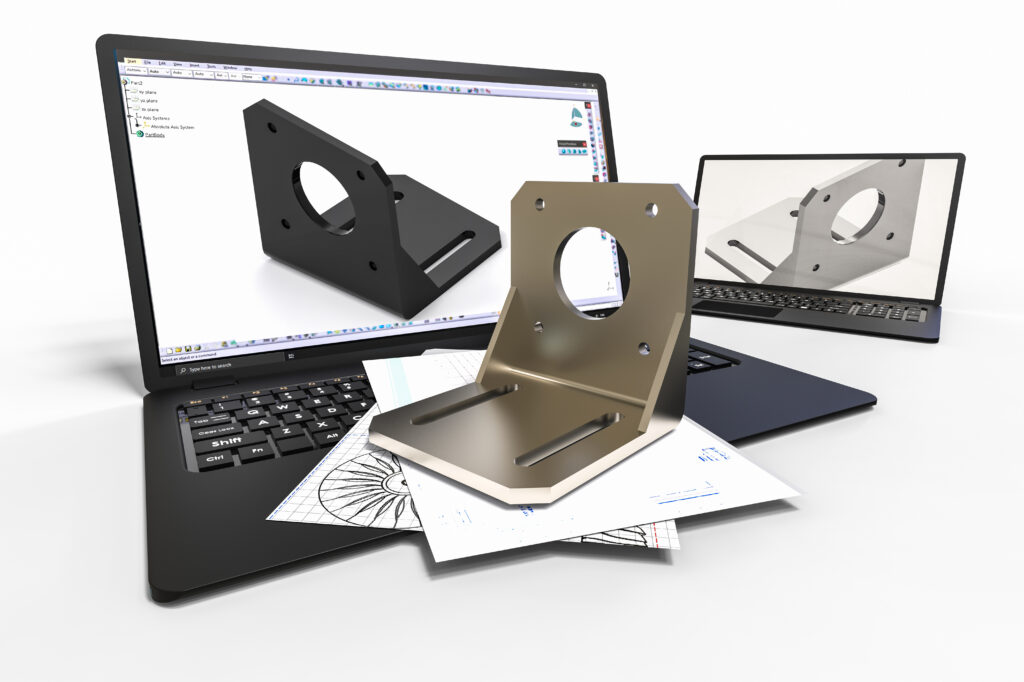

Sheet Metal Fabrication

Get custom sheet metal parts within 1 day.

Instant online fabrication quote on custom formed sheet metal prototypes and production parts. Ideal for both one-off prototypes and end-use custom parts.

Sheet Metal Fabrication Services

Completed operations include Laser Cutting, Punching, Material Graining, Drilling – Countersinking – Tapping, Forming, Hardware Insertion, Mechanical Assembly, TIG, MIG & Spot Welding, Welded Assemblies & Frames, Surface Finishes.

Laser Cutting

Imagine turning a blank sheet of metal into something amazing! For metalworkers, that journey starts with cutting the metal to size and shape. The thickness of the metal and the final design determine how they’ll tackle this first step. One popular and super-accurate method is laser cutting.

This high-tech process uses a powerful laser beam to precisely slice through the metal, allowing for intricate designs and clean cuts.

Punching

Sheet metal punching is a widely used metal fabrication process for creating holes of various sizes and shapes in sheet metal. It utilizes a paired tooling system consisting of a punch and a die. The punch, a shaped tool, presses down on the sheet metal, typically at a corner or edge.

The die, positioned beneath the sheet metal, provides support and defines the final shape of the hole. This efficient process allows for the rapid creation of precise holes in sheet metal components.

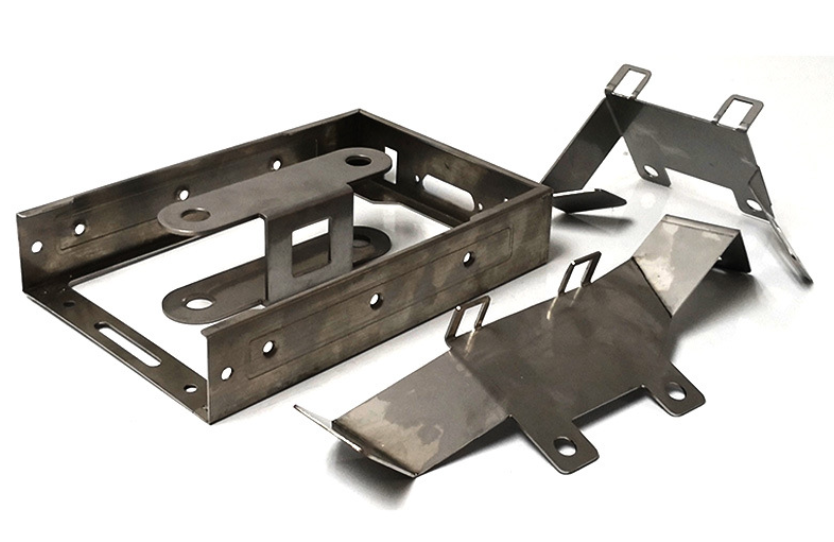

Forming

Unlike cutting, which removes material from a sheet, forming transforms the metal into its desired final shape. This versatile process encompasses techniques like stamping, bending, stretching, and roll forming.

Each method manipulates the sheet metal to achieve specific contours without removing any material. Bending, for example, can be achieved using press brakes or other specialized bending machinery.

Drilling – Countersinking – Tapping

When working with sheet metal, you have a few options to create a smooth, finished look for fasteners. Countersunk holes are drilled with a special bit that creates a wider cavity at the top. This allows the fastener head to sit flush with the surface of the metal, creating a clean and professional look. To screw fasteners directly into the sheet metal, you can use tapping drills.

These drills create threaded holes that accept screws for a secure and permanent attachment.

TIG, MIG & Spot Welding

Choosing the right welding technique depends on the kind of metal you’re working with and the thickness of the materials. TIG welding, with its non-consumable tungsten electrode, is ideal for precise welds on thin sheets of mild steel, stainless steel, or even non-ferrous metals like aluminum or copper.

MIG welding, on the other hand, is a popular choice for thicker mild steel, stainless steel, and even aluminum thanks to its continuous wire electrode feed. If you’re working with sheet metal in a high-volume production setting, then spot welding’s combination of heat, pressure, and speed might be the most efficient option.

Finishing

When it comes to protecting and beautifying your metalwork, there are three key finishing techniques to consider. Sandblasting roughens the surface with a high-pressure stream of abrasive material, creating a good base for paint or other coatings. Buff polishing, on the other hand, smooths and shines the metal using a rotating cloth wheel, perfect for a gleaming finish.

Finally, metal plating or coating utilizes chemical baths to add a protective layer that enhances the metal’s durability, corrosion resistance, and even its visual appeal. These coatings become one with the underlying metal, providing a long-lasting and decorative touch to your sheet metal project.

Advantages of Sheet Metal Fabrication

Sheet metal fabrication brings your metal ideas to life! It’s a versatile process that uses techniques like cutting, bending, shaping, and assembly to turn flat sheets into functional parts.

This makes it perfect for everything from prototypes to large production runs. Sheet metal is especially cost-effective for high volumes because it minimizes material waste. Plus, you get the benefit of precise measurements and clean finishes for a professional look.

Sheet Metal Applications

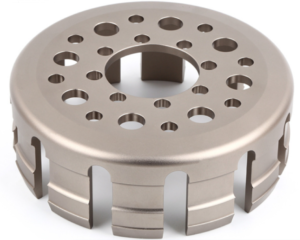

Sheet metal fabrication best its traditional applications in roofing and gutters. Sheet metal has become a super-star in manufacturing all sorts of metal parts. It can handle big jobs, churning out thousands of identical pieces, or create unique, one-of-a- kind works of art. Sheet metal products are used for many purposes, including:

- Architectural products

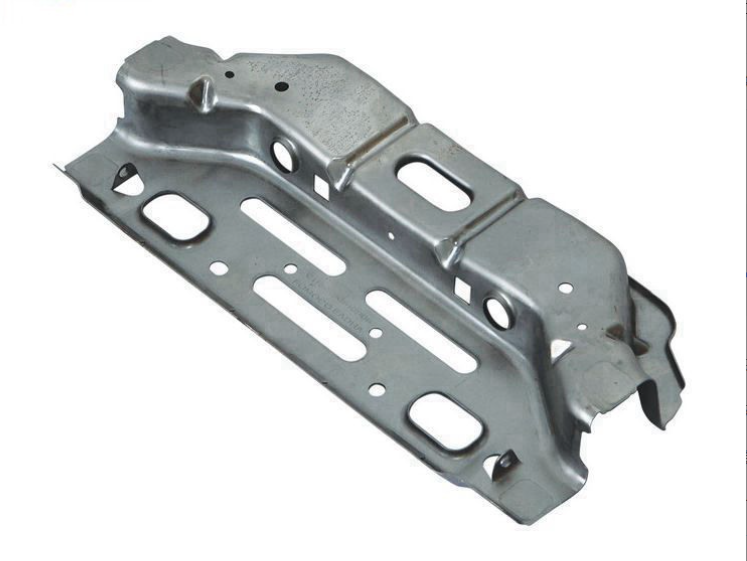

- Automotive

- Aerospace

- Electrical appliances

- Food processing

Available Sheet Metal Fabrication Processes

Our sheet metal fabrication capabilities to serve all your manufacturing needs.

| Name | Description | Allowable sheet thickness |

|---|---|---|

| Laser cutting | Laser cutting is a subtractive manufacturing method that uses a focused laser beam to cut a workpiece. | 1-6mm (depending on material) |

| Bending | Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. | 1-6mm (depending on material) |

Sheet Metal Materials

GY Metal Sheet Fabrication Services simplifies the process of manufacturing custom machined parts. We make it easy for your company to design and implement precision machining solutions.

——————————————

Alloys Available

C11000 / C12000 / C12000 / C360, etc.

Copper C101 / Copper C110

There are a multitude of types of steels for all sorts of purposes, such as stainless steel, carbon steel, and galvanized steel, but the metal as a whole is known for its durability and strength. Lower-carbon content steel may be found in railings or fences, while medium carbon content steel is used for cars and appliances. The highest carbon content sheet metal is frequently found in steel wires. Stainless steel is used for cookware, medical instruments, and many other products.

Titanium has the lowest density of all metallic elements. Titanium alloys are 50% heavier than steel but 7-10 times stronger. Can be anodized in many colors.

Corrosion resistant, even in sea water, aqua regia and chlorine. Also, it is non-toxic, non-allergenic and perfectly compatible with the human body.

——————————————

Titanium Materials Most Used

TA1/TA2

Surface Finishing

We offer a wide range of surface finishes applicable to plastics and metals.

This is the standard choice, economical and rapid, the parts’ surface will leave visible machining marks. The surface finish is equivalent to 3.2RA μm (125 RA μin).

Polishing is to make the surface smooth by physical friction processing, it is often used to prevent corrosion and remove oxidation. After polishing, the parts have a smoother and brighter finish.

Bead blasting is the process of spraying abrasive on the surface of parts under high pressure, after sandblasting, the metal parts have a satin texture or frosted surface, eliminating the processing marks.

Electropolishing is the reverse process of electroplating, which simplifies the metal surface at the micro-level through chemical solution. After electropolishing, metal parts can be brighter and reduce surface roughness.

The black oxide is a chemical conversion coating, it is produced by a chemical reaction between iron and oxide salt in black oxide solution. The corrosion resistance of parts can be improved after black oxidation. Usually for iron, stainless steel parts.

High glossy black / matte black.

Powder coating is a dry coating process used as a metal finish mostly on industrial equipment. A layer of solid and colorful polymer coating on the surface of parts, so as to improve the wear resistance and corrosion resistance.

Additional Processing Services

Our one-stop solution provides assembling, packaging, inspecting, and other services, to save your time and cost. You will get the finished products in one place. Cost? No extra service cost.

Assembly Line

Inspecting

Packing

Why Choose US?

Working with market leaders in the On-demand manufacturing industry, without the busyness and risk.

No MOQ

One-off aluminum prototype part or large quantity parts. No matter the size of your order, we can handle it.

Low Cost

After 12 years of experimenting with new technologies, GY has come up with high-quality products at cheap rates. You can trust us for reasonable prices.

Fast delivery

We have 40 machines with a whole production process, take your project from design to delivery faster than our competitors.

Experienced Engineers

High Precision

The reliability and durability of any product depend on its precision. We ensure to provide you with exact pieces to boost productivity.

Wide Range of Finishes

We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

Sheet Metal Fabrication – The Ultimate FAQ Guide

In our guide below, we have put together the most useful questions about Sheet Metal Fabrication, with the help of our experts.

So, let’s get started!

Get A Quick Quote

We always insist on high quality and cost-effective products, contact us today to get an accurate quotation.

Table of Contents