Precision CNC Machining Service

Get custom plastic or metal parts within 1 day.

- Multi-axis CNC milling

- Five-axis machining

- CNC turning and lathe

- EDM machining

- EDM wiring

- Grinding

- Precision tooling

- Prototyping

- 3D Prototypes Parts

- Build to print

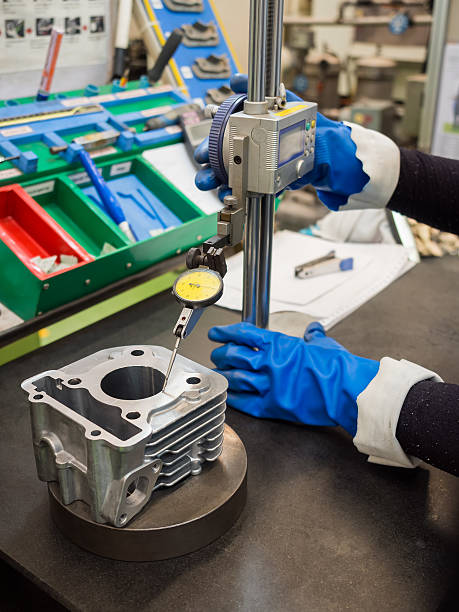

- CMM inspection

- Casting

- All uploads are secure and confidential.

- All uploads are secure and confidential.

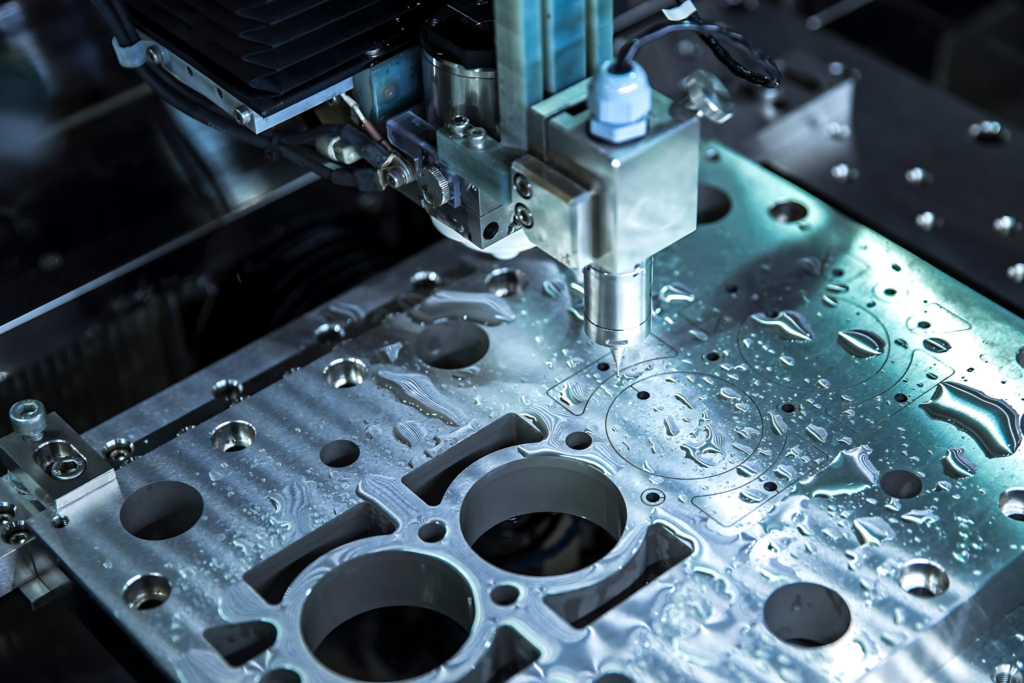

CNC Milling

Imagine a multi-axis robotic arm wielding a cutting tool. This is essentially what a CNC milling machine does. The tool removes material from a solid block, following a programmed path to create the desired shape. CNC milling is versatile and excels at producing complex parts with intricate features like pockets, slots, and contours.

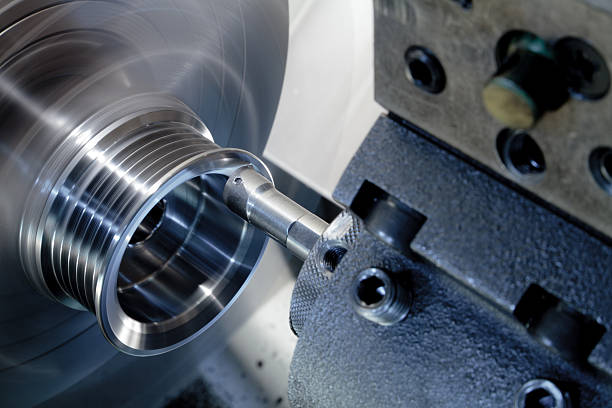

CNC Turning

This method utilizes a rotating workpiece and a stationary cutting tool to make custom turned parts. The workpiece spins at high speed while the tool precisely removes material to create cylindrical shapes. Ideal for parts like shafts, gears, and bushings, CNC turning offers a fast and efficient way to produce symmetrical parts.

Wire EDM

We operate state-of-the-art, submerged machines equipped with advanced automation features. This includes automatic threaders for unattended operation of multiple parts, sophisticated flushing systems for optimal cut consistency, and software that intelligently compensates for wire deflection.

This technological foundation enables us to deliver not only prototypes but also high-volume production runs with unwavering repeatability.

We achieve remarkably fine surface textures, typically in the range of 8-16 μin Ra (0.2-0.4 μm Ra), directly from the machine. This reduces or even eliminates the need for secondary finishing, saving you time and cost.

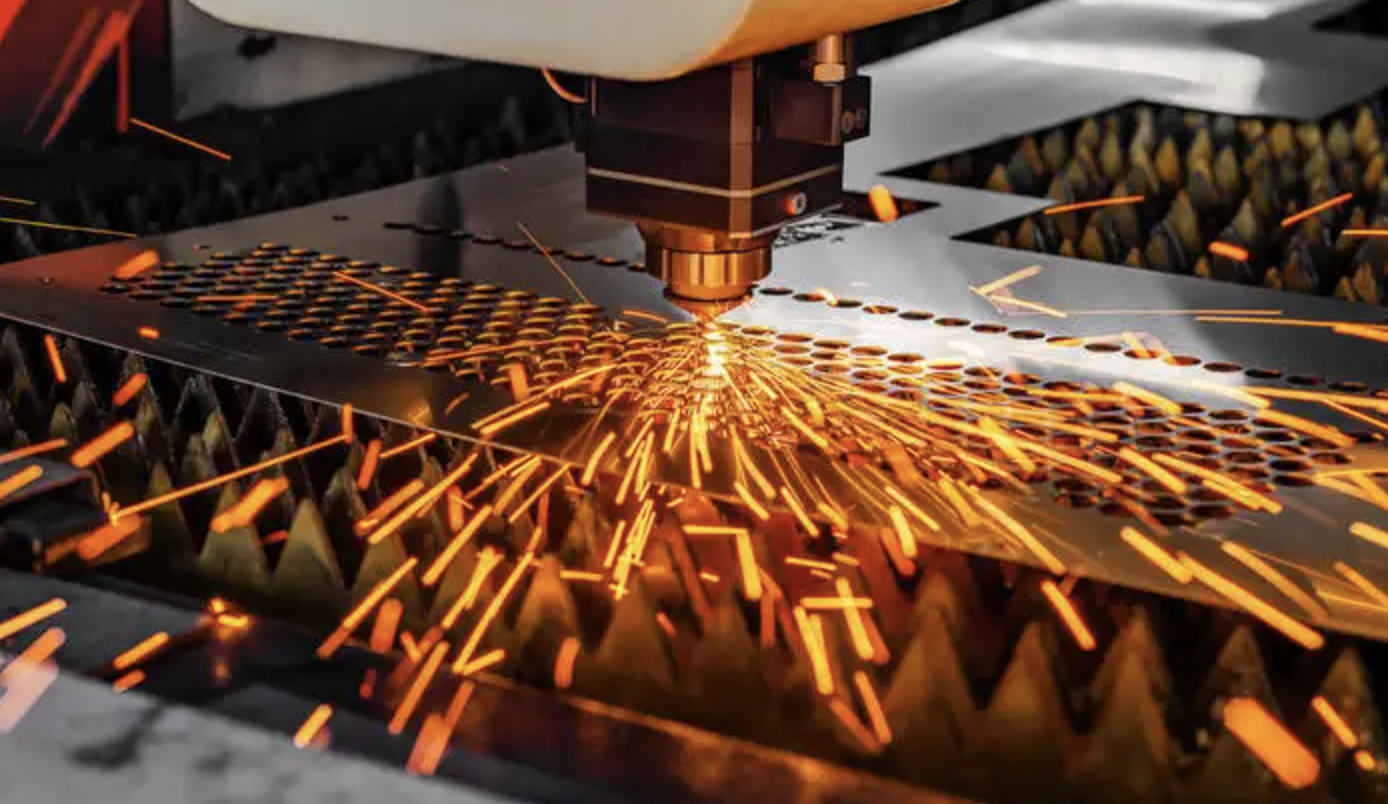

CNC Laser Cutting

For projects requiring precise cuts in sheet metal, our CNC laser cutter is the ideal choice. This advanced technology employs a high-powered laser beam to cleanly and efficiently cut intricate and complex shapes from a variety of sheet metal materials. Our advanced nesting software optimizes material layout from your CAD files, maximizing yield and minimizing waste.

Capable of achieving feature tolerances within ±0.005″ (±0.127mm), our lasers effortlessly produce complex geometries, intricate patterns, and clean, sharp edges. From rapid prototyping to full-scale production, we handle both the simplest outlines and the most demanding designs.

Our expertise spans a wide range of materials, including:

Metals: Mild steel, stainless steel, aluminum, brass, and copper.

Specialty Alloys: Titanium and other high-performance metals.

Plastics: Acrylic, polycarbonate, ABS, and more.

Swiss Machining

For projects requiring extremely small, high-precision components with intricate details, Swiss machining offers unparalleled capabilities. This specialized CNC technique uses lathes with additional functionalities like multi-axis machining and live tooling. Benefits of Swiss machining include:

Microscopic Precision: Swiss machining achieves exceptional accuracy and tolerances, ideal for miniature components in medical devices, electronics, and aerospace applications.

Complexities Made Simple: Swiss machining tackles intricate details and features with ease, allowing for the creation of highly complex parts in miniature sizes.

A Streamlined Project Workflow

Free Consultation

Discuss your project requirements with our experienced team. We'll answer your questions, offer expert advice, and provide initial project feasibility analysis.

Design Review and Quote

Send us your CAD files (we accept industry-standard formats like e.g., STEP, IGES. Our team will review your design for manufacturability and provide a competitive quote.

Project Approval and Production

Once you approve the quote, we'll begin production using our advanced CNC machines and rigorous quality control processes.

On-Time Delivery

We prioritize timely delivery and keep you updated throughout the production process. You'll receive your high-quality, precision CNC parts exactly when you need them.

Tolerances For CNC Machining

| Process | Tolerance(mm) |

| CNC Milling | ±0.005(metal) / ±0.05(plastic) |

| CNC Turning | ±0.005(metal) / ±0.05(plastic) |

| CNC Grinding | ±0.005(metal) / ±0.05(plastic) |

| The Best Surface Finishing | Ra0.1 |

Gallery for What We Did Before

We picked out some of projects we’ve done before, not only these, but more!

CNC Machining Materials Available

We can generate instant machining quotes for 50+ metals and plastics.

- We can source any other material on request, but quotes take up to 48 hours.

Surface Finish

We offer a wide range of surface finishes applicable to plastics and metals.

Powder Coating

Anodizing

Tumbled

Sand Blasting

Brushing

Buff Polishing

Plating & PVD

Black Oxide

what sets us apart

Why Choose US?

Unmatched Expertise

With years of experience and a team of highly skilled machinists, we possess the expertise to tackle even the most challenging projects.

Commitment to Quality

We are ISO-certified and use the latest technology to ensure every part meets your exact specifications. Our dedication to precision machining guarantees consistent quality and exceptional performance.

Fast delivery

We have 40 machines with a whole production process, take your project from design to delivery faster than our competitors.

Don't just take our word for it!

We’ve manufactured millions of parts for all sorts of applications, but we’re especially knowledgeable in these areas.

Military

High-tolerance military grade custom parts. ODM & OEM defence machining parts.

Automotive

Automotive custom CNC machined parts. High-performance engine blocks for EV vehicles.

Medical

Prosthetics, surgical instruments, Implantable Devices with Precision CNC Machining.

Aerospace

Lightweight, high-strength CNC machined aircraft parts. Get highest precision and accuracy.

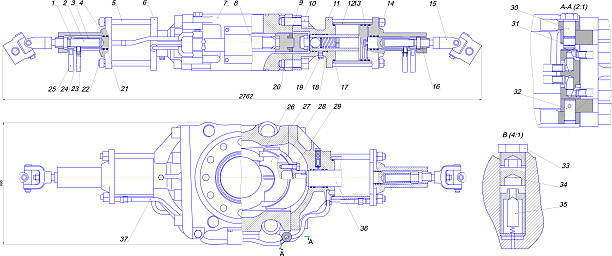

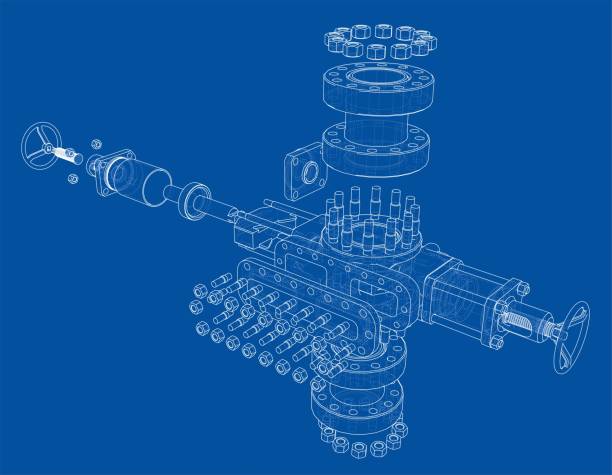

Technical Drawings of CNC Machined Parts

CNC Machining Diagrams Example

CNC machining offers several advantages over traditional machining methods.

Accuracy and Repeatability

CNC machines eliminate human error, resulting in parts that are consistently precise down to the most minute detail. Once a program is set, every part produced will be identical, ensuring unmatched consistency in your projects. This ensures components meet exact specifications with high accuracy.

Crafting Complex Geometries

Unlike manual machining, CNC technology tackles intricate designs with tight tolerances and complex features. Think gears with interlocking teeth, medical implants with smooth, biocompatible surfaces, or intricate aerospace components – CNC machining handles them all with ease.

Versatility Across Materials

CNC machines can work with a wide range of materials, from the ever-popular and lightweight aluminum (a favorite for its strength-to-weight ratio) to tougher materials like steel and even exotic options like titanium. This broadens the applications of CNC machining significantly.

CNC Machining

Frequently Asked Questions (FAQ)

Find quick answers to our most common questions about materials, tolerances, order process, and design guidelines. This resource is designed to help you make informed decisions and accelerate your project.

Q: What is precision machining?

A: Precision machining is a manufacturing process that utilizes computer-controlled machines to remove material from a workpiece with exceptional accuracy and repeatability. CNC (Computer Numerical Control) machines follow precise instructions to achieve tight tolerances and create complex features. This process is ideal for parts requiring high precision and consistent quality.

Q: How much does a CNC machine cost?

A: The cost of a CNC machine can vary greatly depending on several factors, including:

- Type of CNC machine: Milling machines generally have different price points compared to turning centers or specialized machines like laser cutters.

- Size and capabilities: Larger machines with more advanced features will naturally cost more.

- Brand and manufacturer: Different brands offer varying price ranges.

The cost can range from tens of thousands of dollars for a basic machine to hundreds of thousands for highly sophisticated models.

Q: How many axis in a CNC machine?

A: The number of axes in a CNC machine determines the complexity of parts it can create. A 3-axis machine can move the cutting tool along the X, Y, and Z axes, enabling machining of flat surfaces and simple 3D geometries. Machines with additional axes (4-axis, 5-axis) offer more movement freedom, allowing for machining of complex shapes and angles.

Q: How to calculate machining cost for CNC machines?

A: Calculating CNC machining costs can be complex and involves factors like material cost, machine setup time, machining time per part, and overhead costs. Specific software is often used by CNC machine shops for accurate quotations.

However, some general considerations include:

- Material cost: Research the cost of the material you’ll be using.

- Machining time: Estimate the time it might take to machine a single part based on its complexity.

- Machine shop rates: Inquire about the machine shop’s hourly rate for CNC machining.

By multiplying these factors, you can get a rough estimate. It’s important to remember that this might not be a precise figure, and consulting a professional CNC machining service is recommended for a detailed quote.

Q: What is approximate cost of CNC machining cost?

| Part Complexity | Material | Approximate Cost Range |

| Simple (2-axis machining, minimal features) | Aluminum | $1 – $10 |

| Moderate (3-axis machining, some pockets and slots) | Aluminum | $10 – $50 |

| Complex (3+ axis machining, intricate features) | Aluminum | $50 – $200+ |

| Simple (2-axis machining, minimal features) | Steel | $5 – $20 |

| Moderate (3-axis machining, some pockets and slots) | Steel | $20 – $100 |

| Complex (3+ axis machining, intricate features) | Steel | $100 – $500+ |

| Simple (Limited features) | Plastics (ABS, Acrylic) | $5 – $20 |

| Moderate (Complexities requiring multiple setups) | Plastics (ABS, Acrylic) | $20 – $100 |

Similar to machine cost, CNC machining project costs depend on several variables:

- Complexity of the part: Intricate designs with tight tolerances will require more machining time and potentially specialized tooling, leading to higher costs.

- Material selection: Materials like exotic metals or specialty plastics can be more expensive than common materials like aluminum.

- Volume of parts: Larger production runs generally benefit from economies of scale, lowering the cost per part.

Q:What is CNC machining feeds and speeds?

A: CNC machining feeds and speeds refer to the rate at which the cutting tool moves (feed rate) and the speed at which it rotates (spindle speed) during the machining process. Selecting the right feed and speed is crucial for:

- Part quality: Improper settings can lead to surface imperfections, tool wear, or damaged parts.

- Machining efficiency: Optimal settings ensure efficient material removal and minimize machining time.

CNC machines can be programmed with specific feed and speed values based on the material being machined and the desired outcome. Machinists often rely on experience and reference data to select the most appropriate settings.

Q: Give CNC machining examples?

A: CNC machining is used in a wide variety of industries to create a vast array of parts. Here are some examples:

- Aerospace components: Engine parts, landing gear components, and lightweight structural elements.

- Medical devices: Surgical instruments, implants, and prosthetic limbs.

- Automotive parts: Engine components, transmission gears, and intricate housings.

- Consumer electronics: Cell phone casings, computer components, and intricate parts for various devices.

- Prototypes: Fast and efficient creation of prototypes for product development and testing.

Q: What materials can be CNC machined?

A: We can machine a wide range of materials at GY Machining, including various metals (aluminum, stainless steel, brass, etc.) and plastics (Delrin, ABS, nylon, etc.). The best material for your project depends on factors like strength, weight, and application.

Q: What are the benefits of CNC machining?

A: CNC machining offers numerous advantages, including:

* High precision and accuracy

* Ability to create complex geometries

* Consistent repeatability for large production runs

* Shorter lead times for prototypes

Q: Can GY Machining help with sheet metal design?

A: (If applicable) Absolutely! Our team can assist with the design phase of your sheet metal project, ensuring optimal functionality and manufacturability.

We encourage you to contact GY Machining if you have any further questions about CNC machining, sheet metal fabrication, or our services.