Custom Machined Polystyrene PS Parts Made Easy

Get machined plastic Polycarbonate prototypes and production parts at consistently low prices.

- FREE design and solution

- No Minimum Order Quantity

- 100% Quality Guaranteed

- All uploads are secure and confidential.

- All uploads are secure and confidential.

Known as clear or crystal plastic with a lightweight nature, the polystyrene (PS) is one plastic that can do the solid and the foamed form. Widely known for its use in boxes and lab apparatus, PS fills a more or less middle ground. It is a strength and clarity of PS if one can snap up clear food containers or those clever little petri dishes. In addition, it is lightweight, more stable, and safe to use in direct contact with food, which is why this material is widely used in multiple applications.

Features:

- Clear, rigid, brittle, and moderately strong

- Low heat resistance

- Inert, durable and resistant to water damage

- Easily moldable

- Maintains strength in high-impact applications

- Good dimensional stability

- Can be painted

- Good gloss

- Recyclable with good property retention

- FDA compliant grades

- Low volatility

Application:

- Golf clubs and tennis rackets

- Flexible bollards

- Adhesives and sealants

- Wheels: shopping carts, elevators, roller coasters, and roller skates.

- Floorings and infrastructure: hardwood floors and outdoor infrastructure.

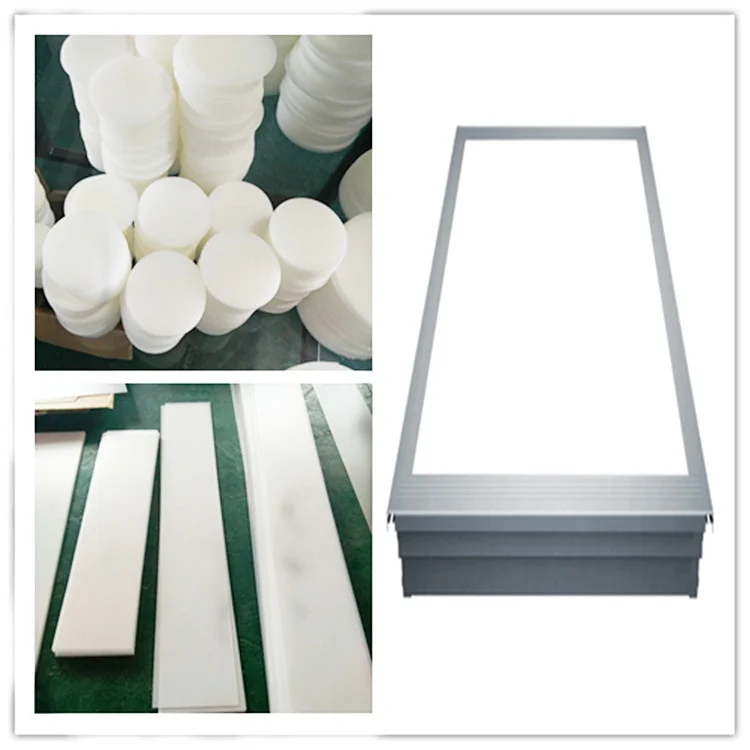

- Foams and cushions: seating, seals, and insulation panels.

- And more…

Frequently Asked Questions (FAQ)

What plastic is PS?

Polystyrene (PS) occurs most frequently in two forms: one as a solid plastic and the other as an expanded polymer that can be used either for foam — commonly known styrofoam. Accordingly, these two PS forms do not possess the same physical properties and hence different applications.

How strong is polystyrene?

The elasticity modulus of polystyrene ranges from 0.7 to 1.4 N/mm2 (760.

What are the three types of polystyrene?

- Solid Plastic. General Purpose Polystyrene(GPPS) High impact Polystyrene

- Foam. Expanded Polystyrene(EPS) Extruded Polystyrene(XPS)

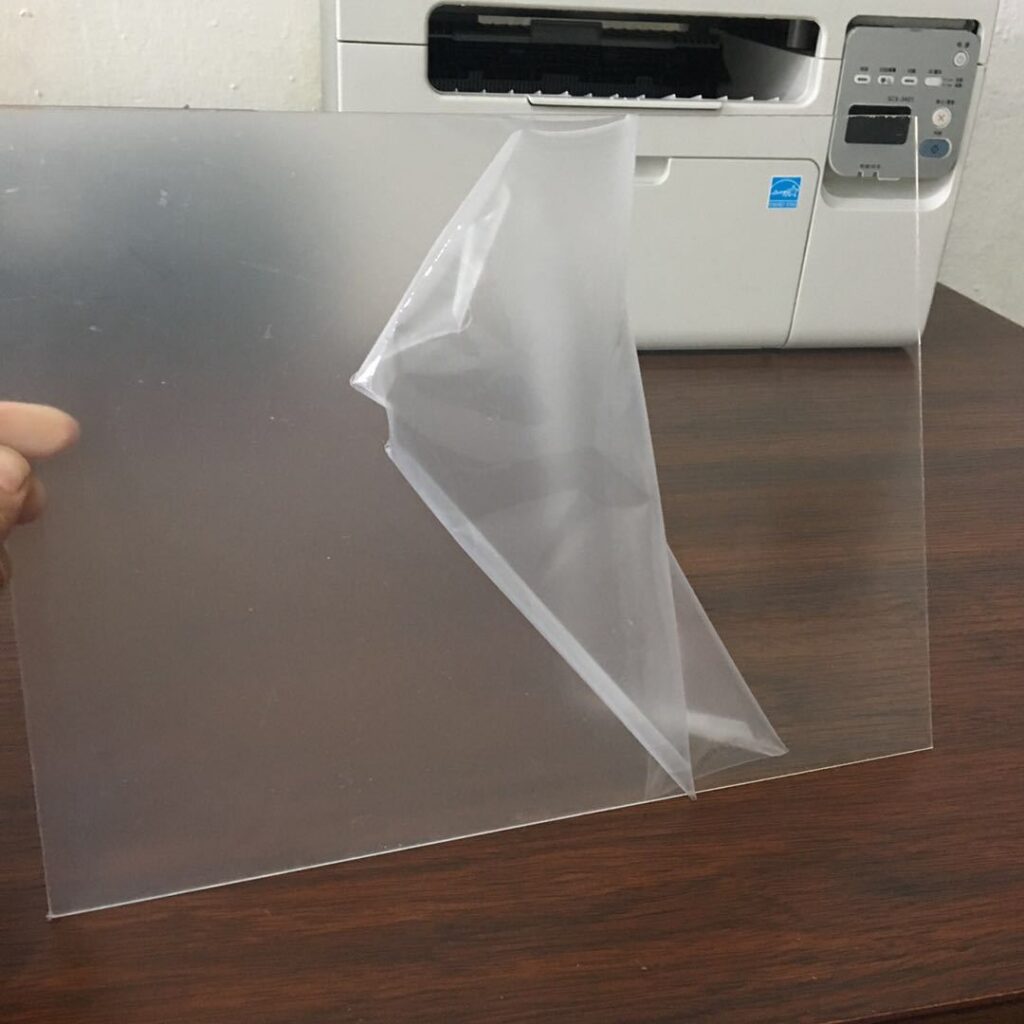

- Films.

Is polystyrene better than plastic?

Polystyrene is less susceptible as compared to other plastics, This means polystyrene does not photolyse so easily i.e. break apart into harmful chemical components in the presence of light. The degradation process could leach toxic substances during up to 500 years of use in the case of a foam coffee cup.

What are the disadvantages of polystyrene?

Disadvantages of Polystyrene include:

- Brittle, poor resistance to organic chemicals.

- Prone to UV degeneration

- Flammable.

Is polystyrene long lasting?

The best thing that can be said about polystyrene is how an item made of it will outlast us by many orders of magnitude, and this characteristic alone makes for one helluva headache. When it comes to the environment, once there due its remarkable chemical stability – some form of PFAS will cycle through for generations.

Is polystyrene rigid or flexible?

Polystyrene is a type of polymer that is transparent, rigid, brittle, and moderately strong in its unmodified state. It is a plastic made by polymerization, which combines the building block compound called styrene

Is polystyrene heat resistant?

Insulation Ingredients * The 2 kinds of foamed polystyrene– EPS as well as XPS (extruded polystyrene) are utilized to protect for 2 factors. Polystyrene in the first place has a high thermal resistance, thus shifting to heat transfer. Second, polystyrene foam is made up of millions of tiny air bubbles which are very poor conductors of heat.

Get A Quick Quote

We always insist on high quality and cost-effective products, contact us today to get an accurate quotation.