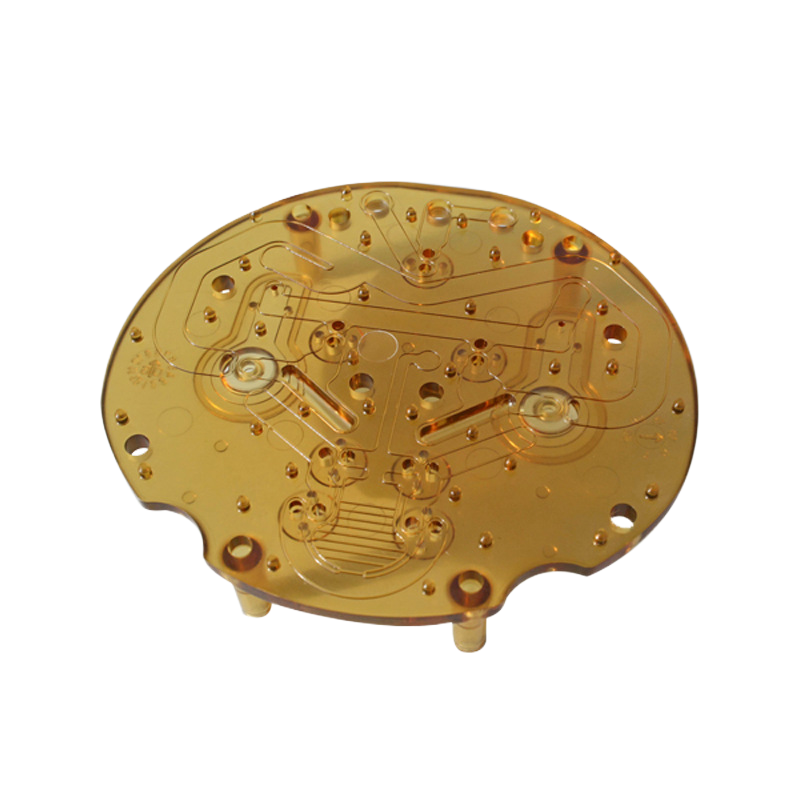

Custom Machined PSU Polysulfone Parts Made Easy

Get machined plastic Polysulfone (PSU) prototypes and production parts at consistently low prices.

- FREE design and solution

- No Minimum Order Quantity

- 100% Quality Guaranteed

- All uploads are secure and confidential.

- All uploads are secure and confidential.

Features:

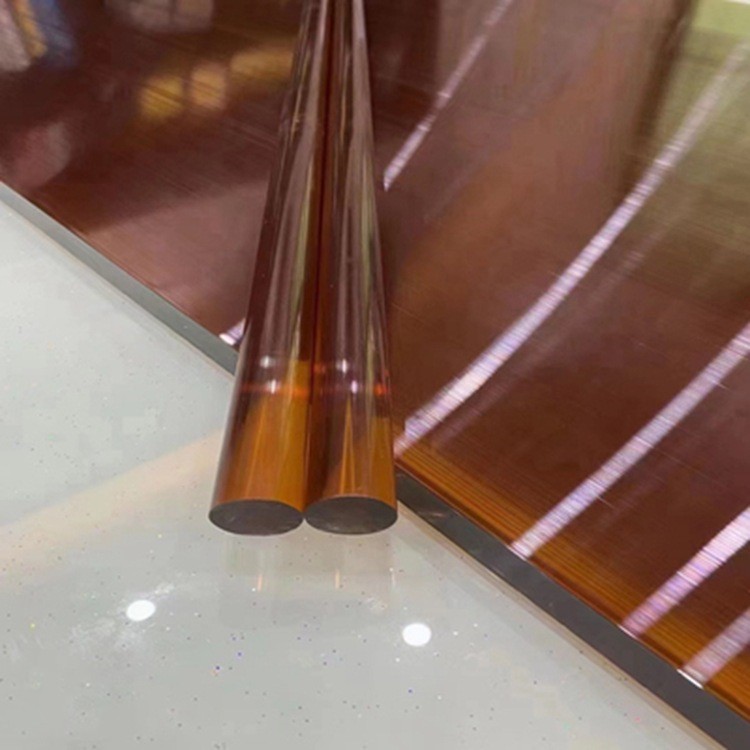

- Semi-transparent plastic

- High operating temperature (160°C)

- Very good resistance to hydrolysis (suitable for repetitive steam sterilisation)

- High toughness, even at low temperatures

- High dimensional stability

- Good electrical insulation

- High mechanical strength

- Strong and stiff

- High creep resistance over a wide range of temperatures

- Good radiation resistance

Application:

- Medical instrument components

- Manifolds

- Medical trays

- Autoclavable instruments and trays

- And more…

Frequently Asked Questions (FAQ)

What is the use of polysulfone?

Laboratory equipment – Polysulfone is widely used in laboratory applications such as test tubes, centrifuge tubes and Petri dishes due to its transparency, strength and chemical resistance.

What are the characteristics of polysulfone?

It has excellent thermal stability, high toughness and strength, good environmental stress crack resistance (ESCR) light weight,transparency or even transparency no colour raw materials as well low creep while also producing heat. Any of the standard process techniques should patter the PSU.

What is the difference between polycarbonate and polysulfone?

Acrylic is the cheapest and used when rigidity matters but toughness does not. Polycarbonate is an incredibly strong material and used in many high impact situations. Polysulfones are more expensive and substituted when limitations to acrylics or polycarbonates exist.

Is polysulfone food grade?

Polysulfone is also food grade and available in custom colors. It is based on an amorphous high performance thermoplastic that offers excellent mechanical and thermal properties, improved chemical resistance over polycarbonate 3A-Dairy compliant. FDA-, NSF-61 listed USP Class VI sanction.

What are the disadvantages of polysulfone?

PSU membranes are bulky in structure, low inter-fiber binding force and the bad mechanical properties.

What are the characteristics of polysulfone?

Some typical properties of PSU are High thermal stability Good toughness and strength Good stress cracking resistance to chemicals at high pH Environmental stress crack resistant Transparency Creep []. Most jackfruit processing methods are the same as for standard fruits, with PSU using mostly traditional postharvest operations.

What is the decomposition temperature of polysulfone?

The polysulfones arc so made contain two carbon atoms in — 0 II repeating units between the sulfone groups, as in I. Thermal decomposition — The principal disadvantage of these polysulfones as engineering materials is their relatively low thermal decomposition temperatures (∼135 °C, R ) -Et, PBS), which are below the melt

Is polysulfone conductive?

Reinventing the wheel in materials design, an unsuspected flexible electrically conductive polysulfone via sulfonation and its application for perovskites solar cells

What is the high temperature of polysulfone?

Polysulfone (PSU)-(semi-transparent, high temperature material) Due to the strength and rigidity, it is a good choice for Robotic Anatomical Uploader, also its steam resistance makes autodaline ideal under autoclave uses. In areas subjected to high temperatures Polywsulfone is dimensionally stable to 300º F. It also has better chemical resistance than Polycarbonate.

Get A Quick Quote

We always insist on high quality and cost-effective products, contact us today to get an accurate quotation.