Custom Machined Clear PMMA Parts

Get machined plastic Nylon prototypes and production parts at consistently low prices.

- FREE design and solution

- No Minimum Order Quantity

- 100% Quality Guaranteed

- All uploads are secure and confidential.

- All uploads are secure and confidential.

PMMA is referred to as acrylic. This is a kind of plastic, which is translucent, rigid material and is highly used in a wide variety of applications. Can you think of a concurrently as strong and transparent material for a glass – that is the miracle of PMMA. Due to its versatility PMMA is available in sheets or rods that makes it very useful when it comes to an object made of cutting and shaping.

But wait there is more: PMMA can be utilized in 3D printing for even more applications in creative work! Thus, next time you encounter something clear and strong, it might well be PMMA making its practical and application oriented cameo.

Features

- Excellent clarity

- Lightweight

- UV resistant

- Good impact resistance

- Outstanding thermal insulator

- Easy to heat-form

- 100% recyclable

Application:

- Lenses

- LCD screens

- Signs

- Skylights

- Sight gauges

- Medical components

- Acrylic nails

- Furniture

- Display rack

- And more…

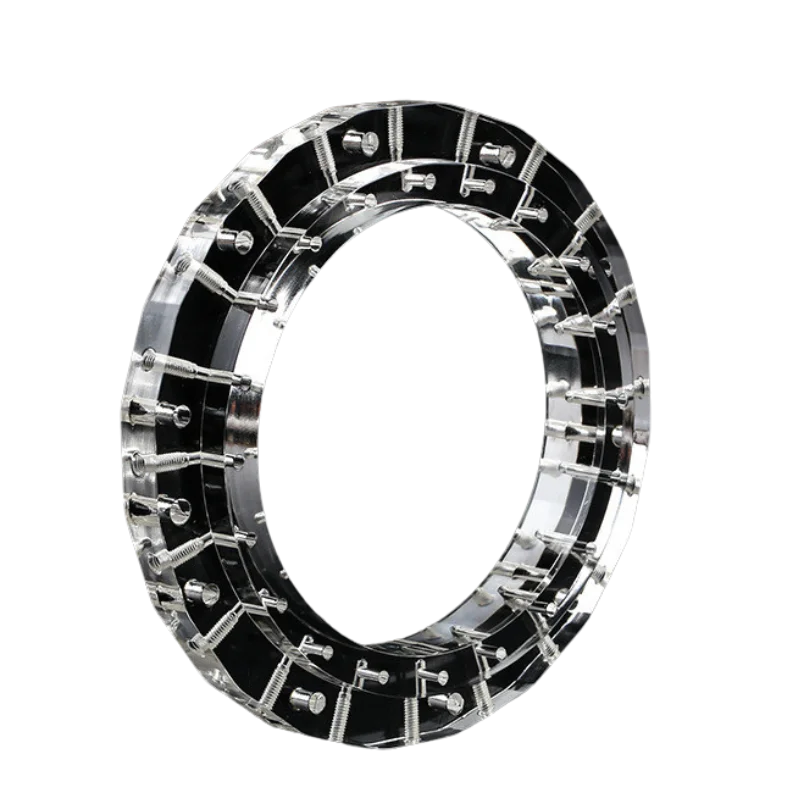

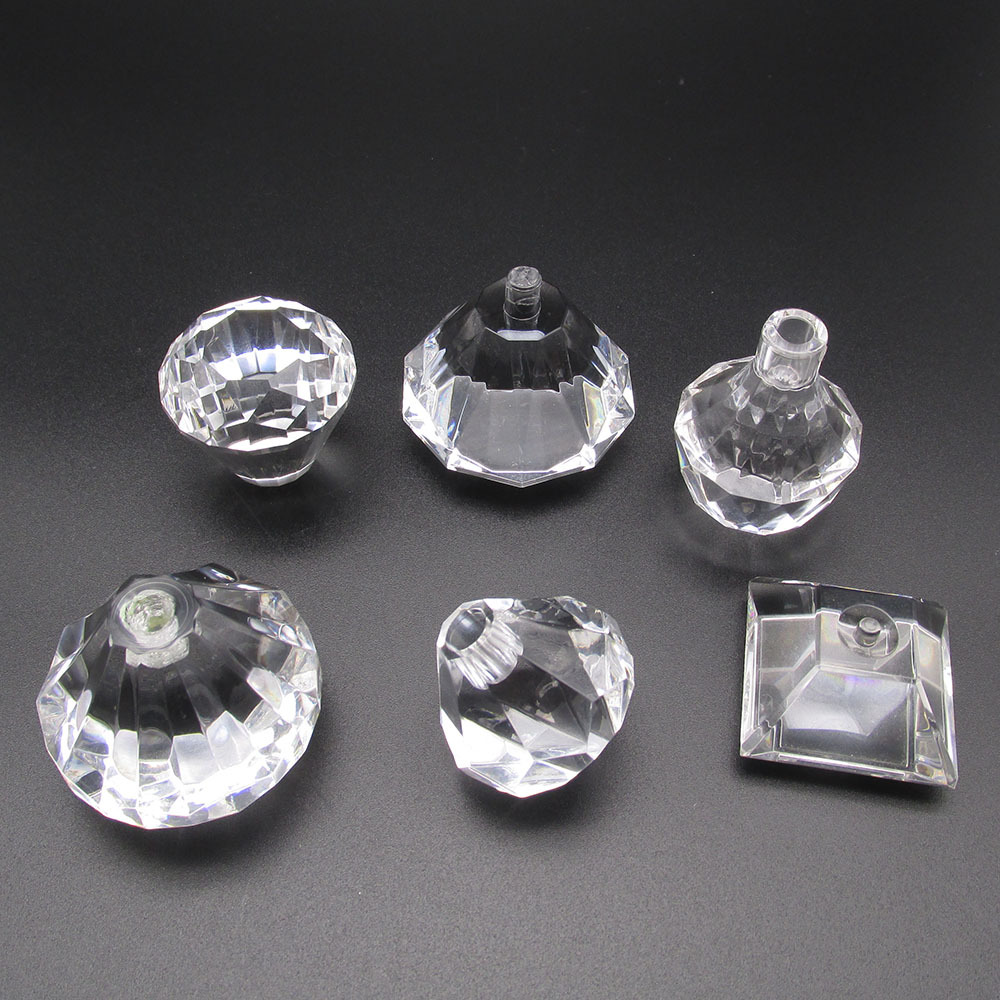

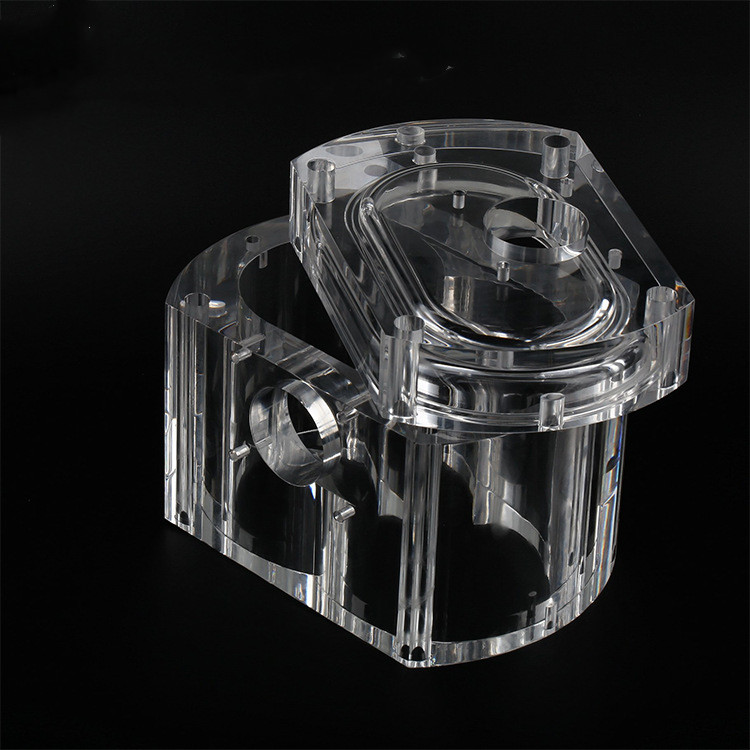

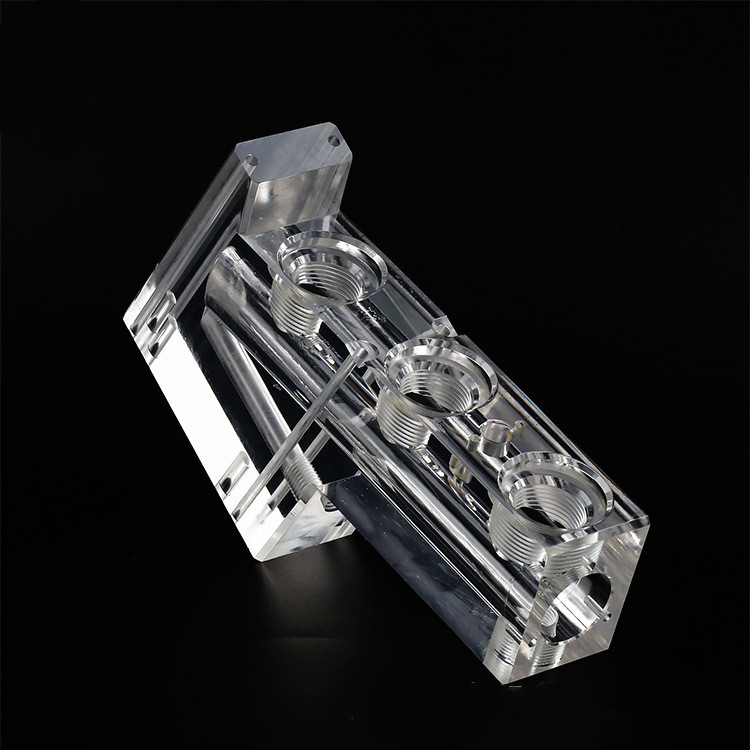

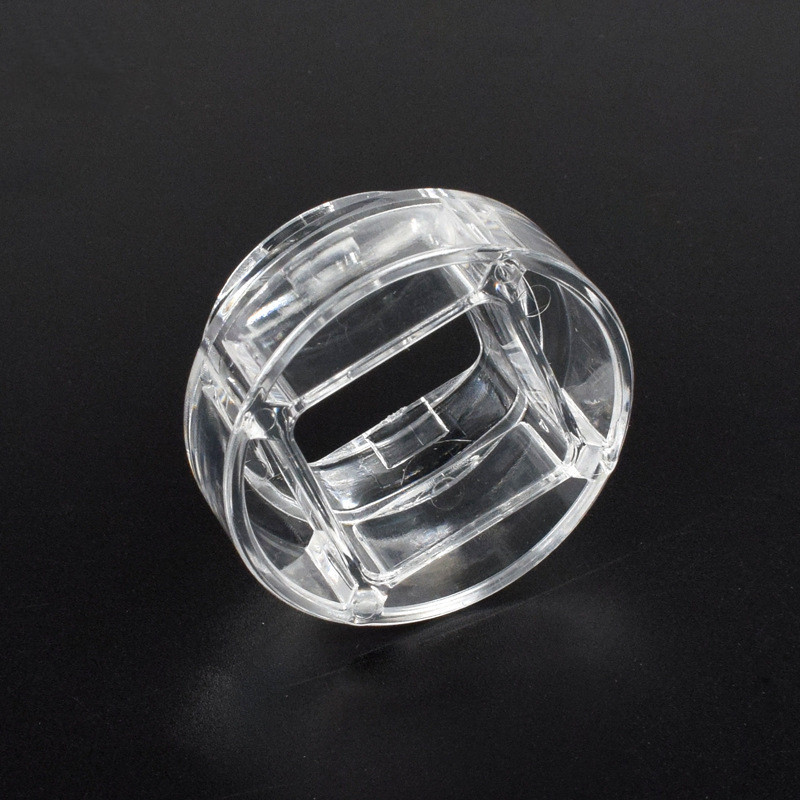

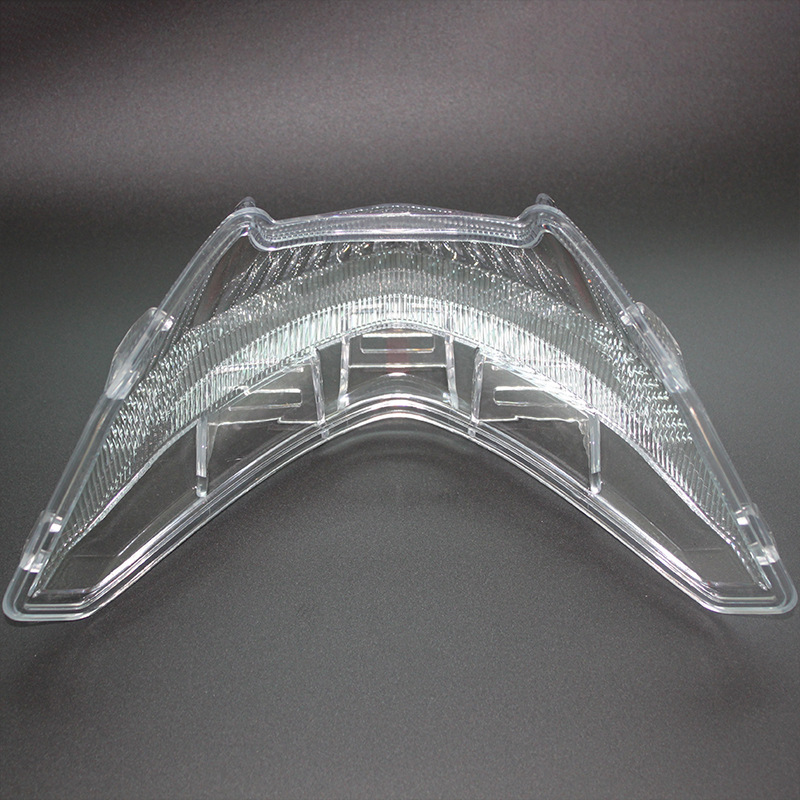

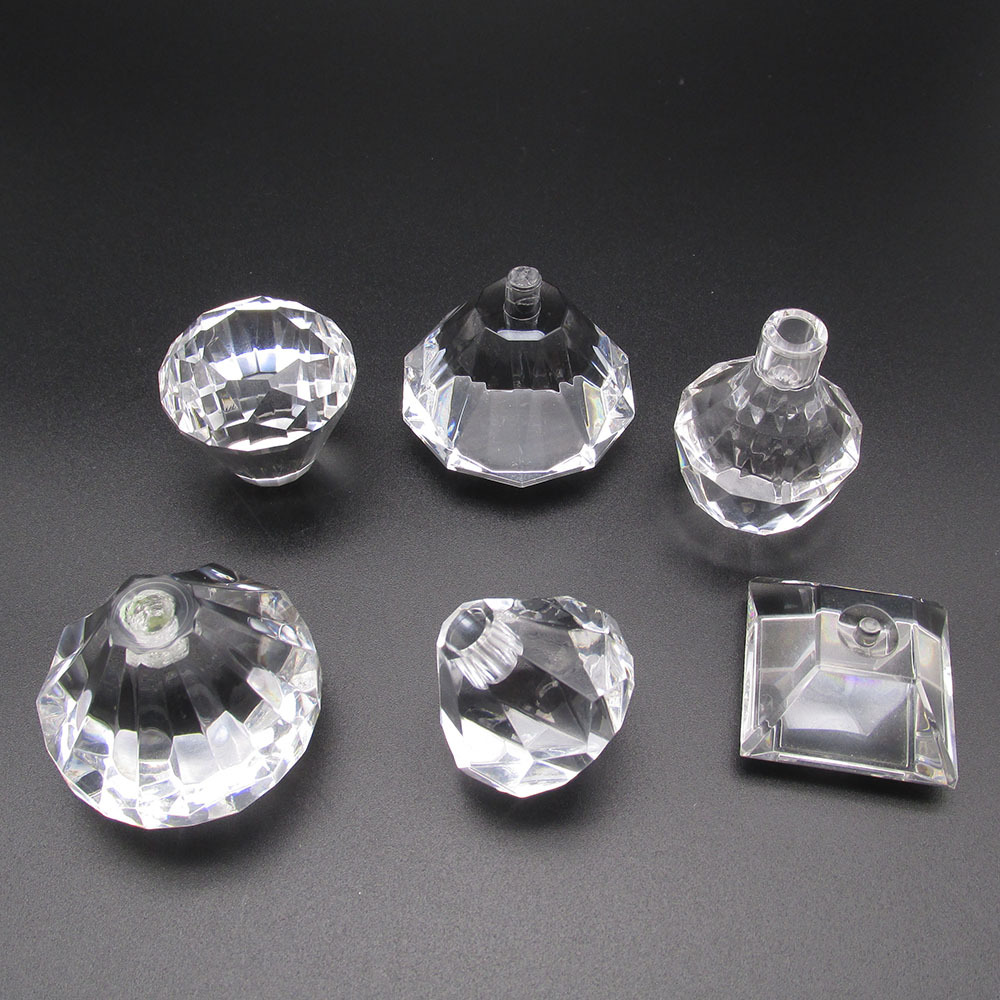

Gallery of PMMA Machining Parts

Frequently Asked Questions (FAQ)

What is PMMA used?

Commonly referred to as Plexiglas or acrylic, pol (methyl methacrylate), abbreviated PMMA Due to its biocompatibility, PMMA material is referred to as bone cement in medical. PMMA is the most commonly used alternative of glass due to a lower weight and also it being shatter-resistant, breaking into large parts when shattered upon hard impact. ok good

Is PMMA breakable?

Unlike most other applications, PMMA does not shatter. No, it shatters into big old nasty looking chunks. PMMA is find as it does not shatter but since PMMA is softer and can be scratched much easier than glass, while some are more scratch-resistant if coated with other materials.

What are the disadvantages of PMMA?

Scratch Resistance: Acrylic is less scratch resistant than glass…

Lithe Solvent Immunity: Acrylic is not highly immune to a variety of solvents, such as acetone or alcohol….

Acrylic is prone to brittleness: Acrylic compared with some other plastics, for example shell can be relatively brittle.

Is PMMA soluble in water?

As PMMA is insoluble in water, to ensure good dispersity of the PMMA particles within water an additional polymer which can achieve effective compatibilisation between the two must be employed

What is the work function of PMMA?

PMMA dictates biomedical applications, e.g., in blood pumps or as a dialyser [13], by its outstanding bio- and hemocompatibility along with the easy handling. Such optical properties suggest that this material would make it as an ideal choice for the use in implantable ocular lens and hard contact lenses.

Is PMMA better than glass?

Below is a structured comparison to help determine which material suits your needs:

| Property | PMMA (Acrylic) | Glass |

|---|---|---|

| Weight | ✔️ 50% lighter than glass | Heavy and brittle |

| Impact Resistance | ✔️ 10–20x more shatter-resistant | Shatters into sharp shards |

| Optical Clarity | ✔️ 92% light transmission (vs. 80–90% for glass) | Slightly less transparent |

| UV Resistance | ✔️ Blocks >90% UV (if UV-stabilized) | Blocks UVB but not UVA |

| Chemical Resistance | ❌ Weak against acetone, alcohol | ✔️ Resists most solvents |

| Machinability | ✔️ Easy to cut, drill, thermoform | Requires specialized tools |

| Cost | ✔️ Generally cheaper (manufacturing + installation) | Higher labor/processing costs |

| Thermal Resistance | ❌ Softens at 80–100°C | ✔️ Withstands >1,000°C |

| Scratch Resistance | ❌ Prone to scratches (hard coatings available) | ✔️ Highly scratch-resistant |

| Environmental Impact | ❌ Petroleum-based, non-biodegradable | ✔️ Recyclable (sand/silica) |

Is PMMA a good material?

Polymethyl Methacrylate is a Thermoplastic Resin with an amazingly large versatility, being used as compared to glass because of its mechanical years and the fact that it is cheap, light weight.

What is the difference between PMMA and acrylic?

Acrylic is a transparent thermoplastic often used as an alternative to glass and polycarbonate (PC); the material has been sold under several different names []. PMMA (i.e., acrylic glass) history is all the way to 1843 when acrylic acid was first isolated.

Does PMMA react with water?

The specificity in the case of PMMA is a presence of an ester functional group (in particular, it belongs to methyl methacrylate), which results with great differentiation between macroscopic properties compared with PAA as i.a. high hydrostability against water concentration.

Get A Quick Quote

We always insist on high quality and cost-effective products, contact us today to get an accurate quotation.

Precision Assembly

We deliver customized precision PMMA plastic parts.

We offer free solutions to your clear PMMA parts, no matter the scale. With our experience, our engineering team will work with you to meet your deadlines and keep costs down.

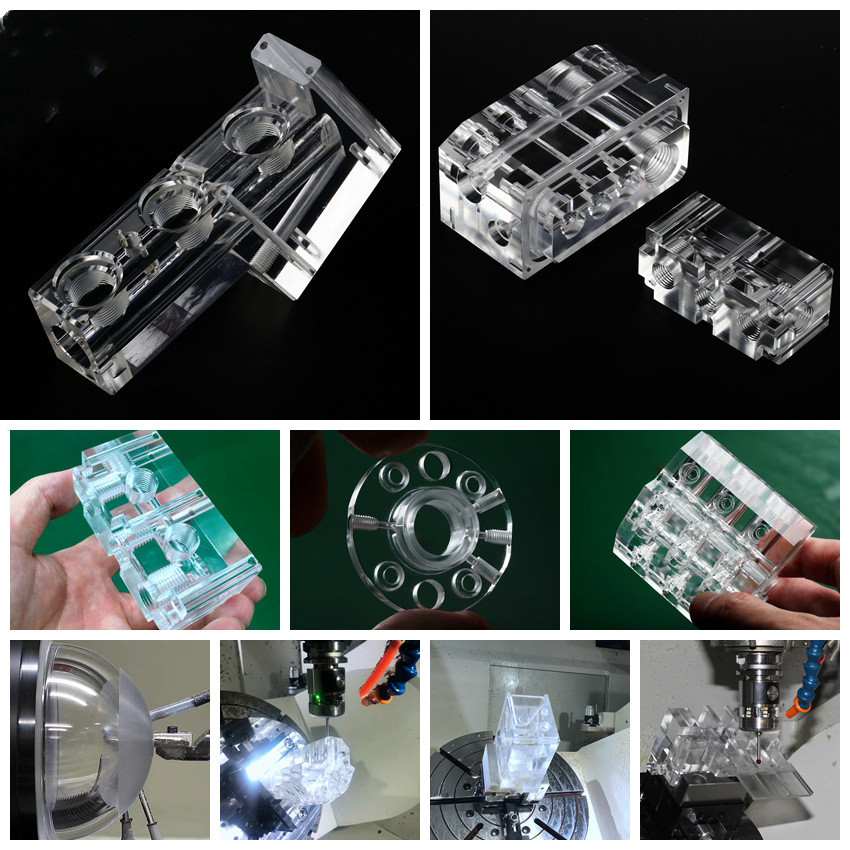

PMMA - CNC Machining Process

Tour Our Plastic CNC Machining Facility

Take a video tour of our CNC Plastic Machining facility to see how our digital process produces quality parts fast. Especially for crystal PMMA parts needs more requirements on techniques.

Work with us to access our vast CNC plastic machining supply chain today.